Porsche 928: What is Engine Knock?

The engine is full of metal components, and a knock is bound to happen. Here is why your engine is knocking.

This article applies to the Porsche 928 (1979-1995).

The Porsche 928 production run spanned across three decades and saw the engine evolve from a 4.5L V8, producing 220 horsepower, to a 5.4L V8, pumping out 350 horsepower. These high-performance engines found in the various 928 models are all susceptible to engine knock. Whether it be from poor fuel quality, poor tuning, insufficient cooling, or a bad knock sensor, it is common for the electronic control module to recognize these problems and reduce engine output and power when engine knock is occurring to protect the well being of the engine. To best understand engine knock, this article will cover basic engine operation, detonation, and pre-ignition. It will also explain what knock sensors are and how they work.

Component Breakdown

Four Cycle Engine Process

The 928 has a four cycle engine. The first step in the engine operation occurs when the air/fuel mixture is drawn into the cylinder during the intake stroke (a). The piston then moves upward and compresses the air/fuel mixture in the compression stroke (b). The spark plug then ignites the air/fuel mixture which forces the piston downwards in the power stroke (c). The piston then travels back upwards and the exhaust exits the cylinder in the exhaust stroke (d).

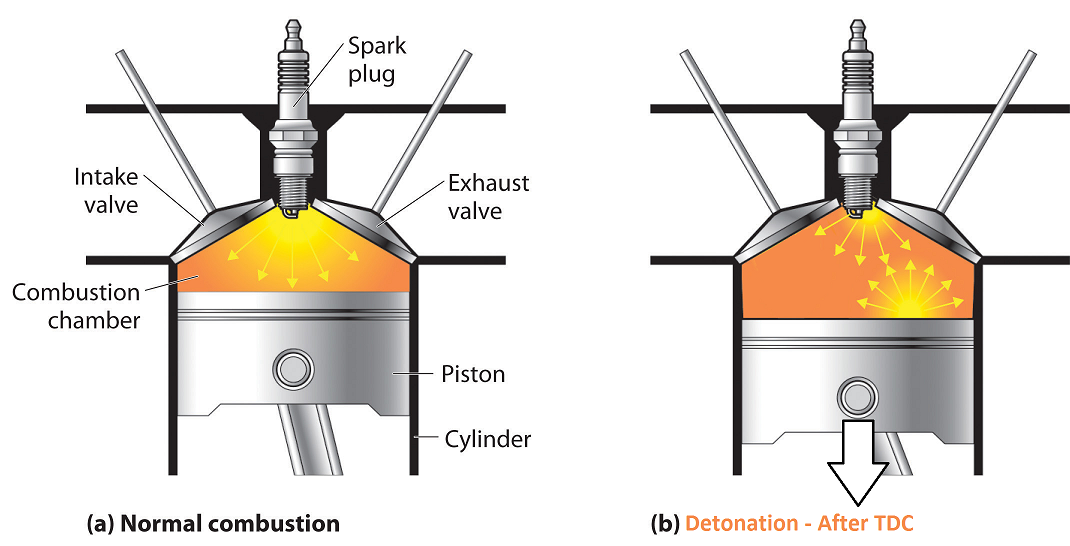

Detonation (Knock)

Detonation occurs after the spark ignites the air/fuel mixture in the cylinder while the piston is traveling downward. This unburned gas, under extreme heat and pressure, ignites and causes a spike in the combustion chamber which we hear as a "ping" or "knock" sound. Detonation is not always destructive to the engine. While it may not be the most favorable running condition for the engine, detonation, or "knocking," will not typically cause instant engine damage.

Pre-Ignition

Pre-ignition and detonation are often used interchangeably; however, pre-ignition occurs before normal combustion as the piston is traveling upwards during the compression stroke. The air/fuel mixture is prematurely ignited and hits the piston with a destructive force. Imagine two hammers being hit together. While detonation, or engine knock, may not be too harmful to the engine, pre-ignition can cause irreparable damage very quickly.

Knock Sensors

The 928 utilizes knock sensors placed in the engine block, which are located underneath the intake manifold. These pieozoelectric sensors are able to determine when engine knock is occurring by converting the frequency of the knocking into an electrical signal. This signal is then sent to the electronic control module which can then adjust various engine functions such as ignition timing to compensate for the engine knock. This process happens very quickly.

Scheduled Maintenance

Although the 928 knock sensors do not have a specified maintenance interval, it is highly recommended that they are replaced whenever the intake manifold is removed. Since they are located in a harsh environment where they are routinely subjected to high heat, the connectors tend to become brittle and can easily break.

Common Questions

How does a knock sensor work?

A knock sensor detects engine detonation and relays this information to the engine's electronic control module. The electronic control module then adjusts ignition timing to prevent detonation from occurring. The timing is typically retarded a few degrees and, as a result, engine power is reduced.

What causes engine knock?

The most common reason for engine knock to occur is poor-quality fuel. With its high-compression engine, the Porsche 928 is designed to run 91 octane or higher. Higher quality fuels have more additives to prevent knock or detonation from occurring. Engine knock can also be caused by incorrect ignition timing or worn or defective distributor parts.

Figure 5. 928 distributor cap.

Figure 6. 928 ignition rotor.

What does engine knock sound like?

The sound of engine knock can be described in many ways. Some feel it sounds like a "ping" you may get from tapping a ball peen hammer on a metal surface. Others explain it as a "tapping" or light "clicking" noise. The sounds of "sizzling bacon" or "popping popcorn" are also popular metaphors for the sound of engine knock.

Common Issues

Knock Sensor Failure

The knock sensors can fail in two different ways: They can either become hypersensitive, thus retarding the timing and reducing power and fuel economy, or they will completely fail which will cause the electronic control module to revert to a safe retarded ignition timing setting. They can only be tested with a Bosch Hammer Diagnostic Computer.

Poor Quality Fuel or Wrong Octane

Make sure to use at least 91 octane fuel in your 928. If you are already using high-octane fuel, but are still having knock issues, it may also be worthwhile to try a different brand of fuel from a different gas station. It is not uncommon to get a bad batch of gas from a budget gas station.

Wrong Ignition Timing

The ignition timing is set by loosening the distributor hold-down and rotating the distributor to the left or right. This will advance or retard this timing and can eliminate engine knock. Consult your owner's manual for the specific timing setting for your 928.

Related Discussions

- How to Determine a Bad Knock Sensor - Rennlist.com

- Knock Sensor Location? - Rennlist.com

- How Do Anti Knock Sensors Work - Rennlist.com

- Change Knock Sensor - Rennlist.com

- 928 Intake Removal - Rennlist.com