Porsche 928: How to Cure High Idle

Troubleshooting a high idle issue can be a bit tedious and is often not much fun. A very small change in any one of the various engine components can have a big effect on the way the car idles and drives. So, if your car is not idling at approximately 675 RPM, chances are something is not quite right.

This article applies to the Porsche 928 (1978-1995).

There are various sources that can cause a high idle issue on Porsche 928 models. With the 928's heavy use of electronics and elaborate intake system designs, it can be a bit difficult to track down the problem. Luckily, many of the basic principles when diagnosing idle issues can be applied to the "shark." This article will touch on some of the potential problems that can cause a high idle on your 928 and what can be done to get that idle back within factory spec.

Materials Needed

- Metric wrenches

- Screwdriver

- Mechanics stethoscope

- Metric sockets or nut drivers

Step 1 – Inspect the throttle cables

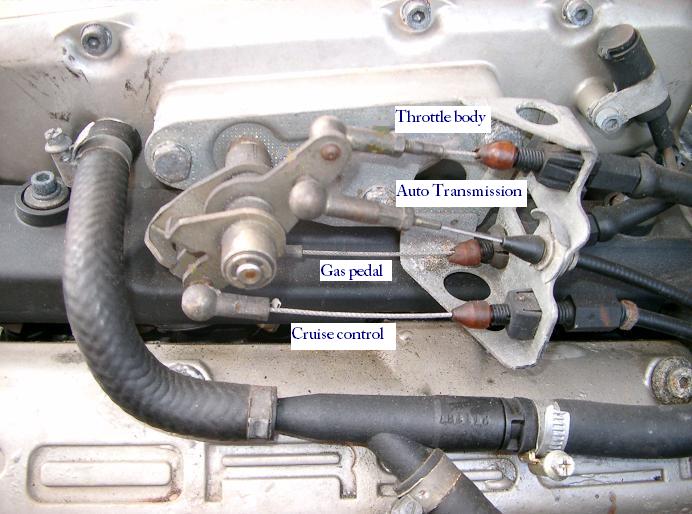

The first and probably easiest component to inspect is the throttle cable adjustment. A cable adjusted too tightly can put just enough tension on the throttle body to open the butterfly valve and allow a bit more air into the engine, hence more fuel and increased RPMs. Throttle cable adjustment is often overlooked, especially if you have been doing any engine-related work and the throttle cable or linkage was removed. The throttle cable should have just enough free play to allow the throttle to be fully closed, but at the same time, have enough tension that there is not excessive slop that must be taken up before the throttle begins to open. Additionally, models equipped with a throttle position switch need to be properly adjusted to ensure the idle and wide open throttle switches are being triggered.

(Related Article: How to Replace TPS on 928 - Rennlist.com)

Step 2 – Check for vacuum leaks

After ensuring the throttle cable tension is set correctly, inspect for vacuum leaks. Small vacuum leaks will allow additional air into the engine that is not measured by the mass airflow sensor and can cause a host of engine performance and driveability issues. However, most vacuum leaks affect the engine's idle.

Testing for vacuum leaks can be accomplished by using an automotive stethoscope to inspect various vacuum line connections. Additionally, the engine can be pressurized, as outlined in the Porsche workshop service manual, to help discover any leaky connections that may be causing high idle issues. Further testing can be done by spraying carburetor cleaner or starting fluid around vacuum lines. If the idle speed increases, then a vacuum leak is present. Be careful with this method as these chemicals are highly flammable. Smoke testing can also quickly identify vacuum leaks.

Step 3 – Check the throttle stop screw

Most 928 owners are not the original owner of their car, so it is sometimes unclear what work has previously been done to their car outside of their ownership. While the throttle stop screw on 928s are set from the factory and not meant to be tampered with, they may have been incorrectly adjusted at some point in the car's life. Similar to a throttle cable that is adjusted too tightly, an incorrectly-adjusted throttle stop screw can hold the butterfly valve open on the throttle body and create a high idle condition.

The throttle stop screw typically has a line painted on it from the factory designating the factory set position. If the painted lines do not match or have worn off from age, it may be worthwhile to check the adjustment. While there is no designated adjustment procedure, you want to first back the screw off to be certain the throttle is completely closed before tightening it to where it makes firm contact with the throttle linkage without moving the butterfly.

Figure 3. Throttle stop screw location.

Figure 4. Throttle stop screw closeup.

Step 4 – Check the mass airflow sensor

As with most engine issues on the 928, the source of a high idle issue could be a failed mass airflow sensor. This sensor measures the amount of air entering the engine and sends this information back to the ECU for fuel trim adjustments to be made. Mass airflow sensors will age over time and become less effective at measuring airflow. Some performance specialists have even stated that a mass airflow sensor out of calibration by as little as 4% will cause issues to one degree or another. Owners have reported swapping their mass airflow sensor with a known good sensor has cured idle issues and improved throttle response & engine performance. Unfortunately, these cannot be tested without a Porsche diagnostic tool. However, with the frequency they go bad, it probably is not a bad idea to have an extra one on hand if a new one does not cure your high idle issue.

Step 5 – Check the idle stabilizer valve and warm-up regulator

- For newer 928 models, an idle stabilizer valve is a computer controlled component that is used to regulate airflow before and after the throttle. Over time, the valve may gum up and stick in one position, causing idle issues. The idle stabilizer valve can be tested by supplying 12 volts across the leads. The valve should fully open with power supplied to it. Additionally, owners have had success in freeing a stuck valve using various cleaners and lubricants. To replace the idle stabilizer valve, the intake manifold must be removed.

- Early 928's with CIS injection systems use a warm-up regulator to adjust fueling depending on engine temperature. This regulator sits atop the motor and uses engine heat to adjust the fuel plunger inside the fuel distributor and changes the fuel mixture. A faulty regulator will disrupt the correct fuel mixture to the engine. The unit can be tested by measuring fuel pressure as the engine warms up.

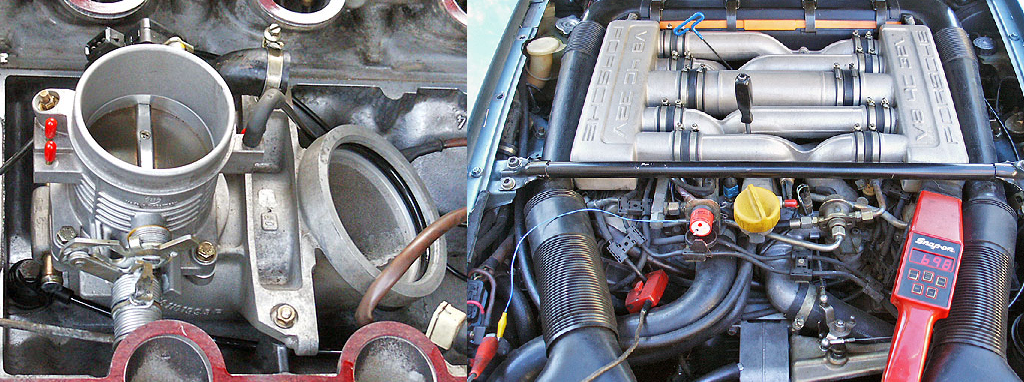

Step 6 – Inspect the idle adjustment screws (K & L-jetronic)

- Early cars equipped with K-jetronic injection have an idle screw and fuel mixture adjustment screw for fine tuning. To lower your idle speed, both the idle and mixture screws must be adjusted together. The mixture screw is what changes the amount of air entering the engine when the engine is at idle, whereas the idle screw controls the fuel. The rule of thumb is that less fuel and less air will reduce the idle speed. Make adjustments in small 1/8 turn increments and keep track of where your original settings were in case you get lost in the process. Turning the adjusting screws clockwise will reduce the air/fuel settings.

Figure 8. K-jetronic adjusting screw locations. - For L-jetronic systems, the idle adjustment is much simpler as there is a single idle adjustment screw located in front of the throttle body. Turn the adjuster clockwise to decrease idle speed and clockwise to increase idle speed.

Figure 9. L-jetronic idle adjustment.

Pro Tip

Before attempting any idle adjustments, be sure there are no engine vacuum leaks.

Related Discussions

- Post Top End Refresh: High Idle - Rennlist.com

- High Idle Speed Suggestions - Rennlist.com

- Testing Procedure for Idle Control Valve - Rennlist.com

- Adjust TPS and Idle Screw - Rennlist.com

- 928 Throttle Cable Adjustment - Rennlist.com