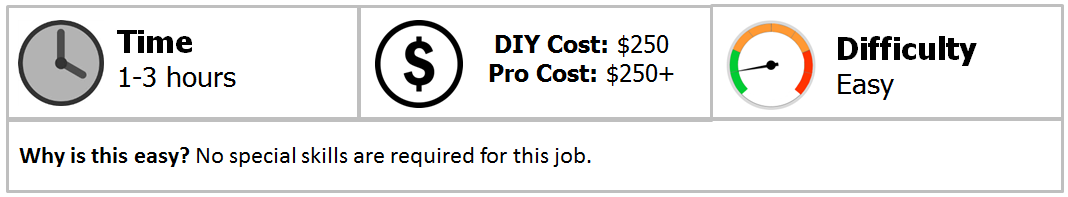

Porsche 993: How to Determine a Bad Knock Sensor

Here's how to replace the knock sensor in your Porsche 993 and get your engine performance back.

This article applies to the Porsche 993 (1993-1998).

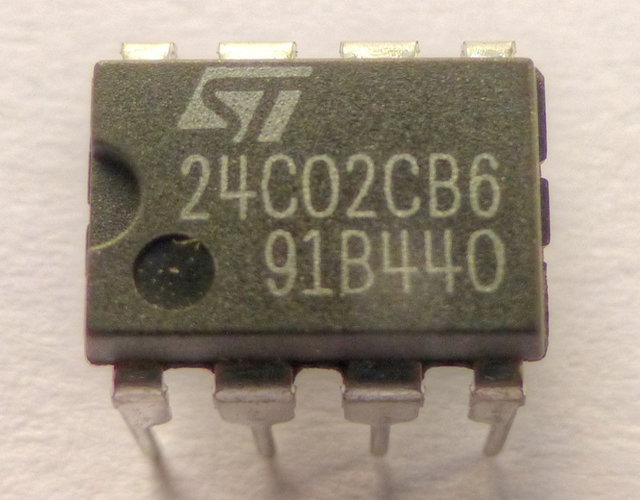

Engine knock occurs when the air/fuel mixture in the cylinder does not combust correctly when the spark plugs are ignited, causing pockets of the mixture to explode erroneously. Your Porsche 993 has two knock sensors, one for each bank of pistons. They sense knocks by way of piezoelectric crystals. These magical crystals have an interesting relationship with electrical charge. If you squeeze them the right way, they produce voltage. If you put voltage across them the right way, they contract. Because of this relationship, piezoelectric crystals – or, to use shorthand, "piezos" – can be used in high frequency speakers, in acoustic instruments to add electric capability, and with internal combustion engines to detect knock.

Your engine senses knock with the same technology in Dave Matthews's guitars. But the sensors themselves are very hardy pieces of gear. If you've got knocking, they might not be a problem. Go through the following steps to narrow things down a bit.

Materials Needed

- Code scanner

- Socket wrench

- Multimeter (optional)

Step 1 – Which octane gas are you using?

We don't have to tell you that Porsches are finely-tuned machines. They deliver a truly amazing amount of performance, but in order to do that they need premium fuel. You should most likely be running 93 octane gas, but you might want to try running 100 octane if your car's got a wild chip in it and you can get your hands on some. If you search around on the internet, you can find companies who will sell it to you. You might have to drive a bit to get to them.

Step 2 – Get your car scanned

Those of you with later year 993s (from 1996 onward) will benefit from OBD-II diagnostics, but most 993 owners will be looking at OBD-I. You can purchase a scanner yourself, but it might be easier to go visit your friendly local mechanic and have them scan your car. With a scan, you might get a bit of information on what the car thinks is wrong with itself. Granted, this is a little bit like asking a child why they are sick. But asking is just one step of the process.

Although not entirely recommended, there are also homebrew 993 scanning tools out there developed by the 993 community. You'll have to search for something called "scantool" and make sure you have the right connector for your model year. You might also have to solder your own connector cable together. Needless to say, this is a route best suited for the experienced DIYer, so beginners beware.

Pro Tip

Getting your car scanned by a pro not only gets you a pro scan, but the valuable insight that a veteran code reader can provide. Sometimes, scans that seem straightforward are actually clues to larger problems.

Step 3 – Is your car chipped?

Some say that power is the most important thing in the world, and that getting more horsepower out of your engine is a simple matter of adding a chip to your ECU. However, it's not that simple.

Porschephiles have been known to modify their cars in all manner of ways. Some are good, some are questionable. But if your ECU has a chip in it that monkeys with the timing in an effort to squeeze more power out of your engine, it might be the cause of your knocking. An experienced technician can tell you for sure if you don't know whether your car is chipped.

Step 4 – Is your distributor drive belt working well?

Porsche wants you to love your car. Not only that, they want you to prove that you love your car by making some things extra difficult. Such is the case with the 993's spark distribution system, which is not one, but two distributors linked by a belt. The primary distributor turns mechanically by way of gearing connected to the engine, but the secondary distributor turns thanks to a belt connected to the first. If that belt fails, distributor two gets depressed and just mopes around without distributing any spark at all.

Pull the distributor cap off your secondary distributor. Can you spin the rotor with your finger? If so, the belt inside doesn't have a grip on it, and that's a problem. You can also try pulling the coil wire to the primary distributor. Try to start your car with it disconnected. If the car starts and runs, that means it's running on distributor two which is turning because of the belt connected to the primary distributor. If not, well, "distributor" starts with "D" and that rhymes with "T" and that stands for "trouble."

Step 5 – Check O2 sensors

In order to manage your AFR (air fuel ratio), your car needs accurate information on the oxygen available to it. It does this by sampling said oxygen with a sensor. If you've got bad sensors, almost any car will let you know with a check engine light. Porsches are no different in this respect. But you can also test an O2 sensor with a multimeter to make sure it's doing its thing. There are lots of how-tos out there on this procedure, so have a little search around.

(Related Article: Porsche 993: How to Replace Oxygen Sensor - Rennlist.com)

Step 6 – Are you experiencing pre-ignition or detonation?

If you've gone through all of the above and the problem is still eluding you, you're probably going to want to visit a shop with an advanced code scanner and the knowledge to interpret its findings. As much as doing things yourself can be rewarding, there's just no replacement for experience. There's also no replacement for top flight scanners. Well, there is. You can buy another scanner, but some of them you can't even buy and have to lease from Porsche. They're great, but not cheap.

Knocking is actually a symptom of one of two problems: pre-ignition and detonation. Pre-ignition is what happens when some hot spot inside the cylinder other than the spark plug's natural firing causes the air fuel mixture to ignite, usually before the spark plug should have fired. Detonation is when the gases ignite purely because they have been compressed enough to explode, usually after the spark plug should have fired. Neither is good.

Engine efficiency and performance are all about timing down to fractions of a millisecond. Imagine a child swinging on a swing. There's an optimum moment to push that child so they swing higher and have more fun. If you push too early, you won't get a bigger swing. You'll actually slow the child down, which will result in an irritated kid and possibly tennis elbow. If you push too late, you'll just be flailing your arms ineffectually in front of you like a crazy person.

Step 7 – Replace the knock sensor

If you're absolutely sure the problem is your knock sensor, the replacement of them is fairly straightforward. They bolt to the top of your engine on either side like so, attaching to a bracket that allows one sensor to listen to three pistons simultaneously.

The other end of the sensor is a three-prong plug that should be an easy disconnect. Remember to avoid torque-ing the sensor end down too much; 15 ft-lbs should do just fine. Of course, as usual with any engine – but especially a rear-mounted one – having room to work can be a struggle.

Figure 5. Side sensor from rear through fan opening.

Figure 6. Driver side through the fan opening.

Figure 7. Sensors from the outside.

Related Discussions and Site

- Checking 993 Cam Timing - Rennlist.com

- Check O2 Sensors - eHow.com

- Bad Knock Sensor - Rennlist.com