Porsche 993: Why Does My Alternator Belt Squeak at Start-Up?

There are a few potential causes to start-up noise in a Porsche 993. Learn about them here.

This article applies to the Porsche 993 (1993-1998).

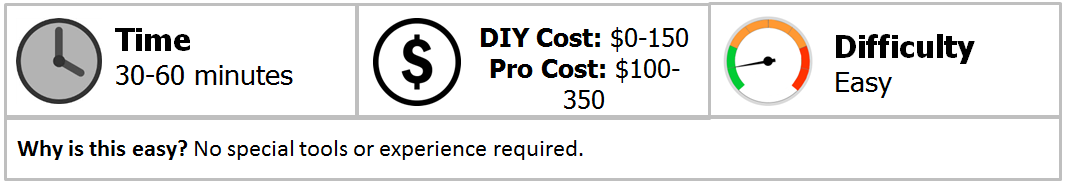

Sometimes, it can be hard to find out exactly where a temporary squeak at start-up actually comes from, but a few easy diagnostic checks will reveal the culprit. There are plenty of things in the engine that can create a squeaking noise, for example, the power steering. However, common areas that are known to squeak, which are also relatively cheap and easy to fix, are related to the belts on the back of the engine. The Porsche 993 has three belts used for different purposes. The belts should be replaced in regular intervals according to the service plan. If you are experiencing a squeaking noise when starting your 993, then refer to the helpful steps below to determine what's wrong.

Materials Needed

- Tape

- Lubricant oil (optional)

Step 1 – The alternator belt roller sensor

The alternator belt roller sensor is located to the left of the inner belt and has the sole purpose of sending a signal to the DME that the belt is spinning as it should. When the roller starts to fail, it usually starts to squeak at start-up in the mornings. Eventually, the problem gets worse and the squeak will remain constant.

With the engine off, put some tape on the roller of the sensor and make sure that it doesn't touch the belt anymore. Start the engine and listen if the squeaking sound is gone. If it is, odds are the roller of the sensor is dry, hence the squeaking. If you remove the tape from the roller and start the engine again, the squeaking sound should come back again.

To fix this problem, remove the alternator belt roller sensor and spray the roller with some lubricating oil. If the belt roller sensor is in very poor condition, then replace it with a new one.

Step 2 – A/C belt

If the A/C is off, then there is little load on the A/C belt driving the A/C compressor. To diagnose if the A/C belt is squeaking, turn the A/C on and off. If you hear a squeaking sound when the A/C is on (or if you use defrost) but nothing when the A/C is off, then your A/C belt is probably the culprit. This means that the belt needs to be tightened or replaced. The belt is tightened by removing shims from the belt pulley; however, while you are at it, you might as well replace the belt. A belt is not very expensive.

Step 3 – Alternator belt

To diagnose the alternator belt, you simply have to put little or more electrical load on the alternator of your car. To increase the electrical load you can switch on the headlights or the rear defroster. If you notice that the squeaking sound appears when you increase the load, then it is likely that the alternator belt is a little loose.

To tighten the alternator belt, you have to remove shims from the belt pulley on the fan. If the belt wasn't replaced recently, or if it shows signs of cracking or drying, you should also consider replacing the belt. In Figure 2 above, the alternator belt is the very top belt shown.

Step 4 – Fan belt

This is a very important belt since it's actually part of the system that keeps your engine cool. This belt drives the fan thus cooling the engine. Inspect the belt and, if you see any signs of cracks or that the belt is dry, replace it. If the belt has been recently replaced and looks fine, it could still be a little bit loose, hence creating a squeaking noise (perhaps only when the engine is cold since when the engine warms up the tension of the belt increases a little). If the belt is too loose, then the belt can be tightened by removing shims from the belt pulley.

Related Discussions and Sites

- Porsche 993: How to Replace V Belts - Rennlist.com

- Squealing Belts - Rennlist.com

- Alternator Belt Noise - Rennlist.com

- Replace Belts - Pelicanparts.com

- Belt Tightening - Wbnoble.com

- Squeal on Start-Up - Rennlist.com